Materials and case frame

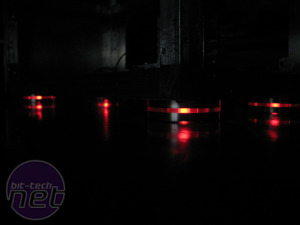

While I was waiting for my acrylic and aluminum to arrive, I was eager to start working. I began construction of the case feet in the work shop. I used some left over 1/4in aluminum plate from my second mod to make four case feet. Each foot has a red LED in it, held in place by hot-glue.When the aluminum finally arrived, I started construction on the frame. I designed the frame to be extra strong in order to withstand the weight of the oil. The final weight of the machine filled with eight gallons of oil is 122lbs. Accordingly, each three way corner is held together with three homemade L-brackets and 12 3/4in screws. Tapping all 220 holes through solid 3/4in bar stock made my arms ache. I now twitch when I hear the word “tap”.

I attached four 1/2in angle risers for the tank to the lower frame. These hold the tank in place, provide strength to the corners of the acrylic, and provide a structure for the top compartment to attach to. At this point, I also started cutting the aluminium sheet to size for the side panels. One of my sponsors, Crystalfontz, provided a CFA635 USB LCD screen. I decided to put this on the front in the lower compartment. This necessitated the fitting of a USB connection in the lower compartment so I installed a USB hub in the rear. I spent hours filing the holes for the USB hub and LCD screen, but the result was worth the time.

Finding mineral oil sold in large enough quantities to fill an eight gallon tank is harder and more expensive than you might think. I work for a power utility and I learned that we use Shell Diala AX in our transformers. I looked up the MSDS sheet for Shell Diala AX to see if it would work for my purposes and discovered that it’s essentially mineral oil with flame retardants added. Perfect. I was able to acquire ten gallons from work free of charge. I was almost ready to buy ten gallons off eBay for $200, so I was pleased to say the least.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.